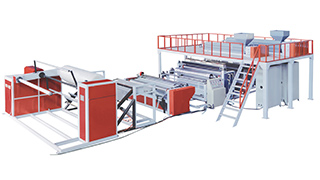

The YHPE-ZLB Double Layer Bubble Film Machine is an excellent piece of equipment. It mainly utilizes polyethylene raw materials to produce double-layer bubble film, which is suitable for packaging fragile items like electronic products, handicrafts, and glass products. This bubble film has outstanding shock absorption and protection performance.

1. Screw Design: It adopts an advanced twin-screw design, which simplifies the production process. This design enables independent and accurate control of the bottom layer and the bubble layer, and the operation is user-friendly.

2. Bubble Formation: Through the perfect combination of the bubble roller and water cooling, bubbles are efficiently formed, achieving fast and high-quality film production.

3. Temperature Control: The equipped PLC system precisely controls and monitors the temperature in real-time. This ensures the stability and safety of the production process, as well as the consistency of product quality.

1. Film Width: The film width ranges from 1200mm to 3500mm, which can meet a wide variety of production needs.

2. Screw Parameters: The screw diameter ranges from φ50 mm to φ105 mm, and the screw aspect ratio is 33:1.

1. Materials and Durability: It uses high-quality materials and advanced manufacturing processes, ensuring both reliability and durability.

2. Cooling Systems: Combined with air cooling and water cooling systems, the water cooling enhances production efficiency and makes the bubble film firm and transparent. Meanwhile, the air cooling meets the requirements of a moisture-free production process.

3. Maintenance: The equipment is easy to maintain, which effectively reduces the cost of use for users.

1. Manufacturing Process: The manufacturing process includes extrusion, molding, traction, and winding. The unique winding and overturning mechanisms make the operation simple and efficient.

2. Product Quality: The one-time molding process ensures that the bubble arrangement is neat and free of defects.

The YHPE-ZLB Double Layer Bubble Film Machine is an ideal choice for enterprises to package fragile items. It has a very high cost performance, providing reliable packaging solutions for enterprises and assisting in their development.

|

Model |

Max.Width |

Screw Diameter |

Screw L:D |

Extruder- Motor Power |

Take-up Motor Power |

Vacuum Pump |

Speed |

Power |

|

YHPE -1200 |

1200mm |

Φ65/Φ50mm |

33:1 |

18.5/11kw |

1.5kw |

1.1kw |

5-30m/min |

70kw |

|

YHPE -1600 |

1600mm |

Φ70/Φ55mm |

33:1 |

22/15kw |

2.2kw |

1.5kw |

5-30m/min |

90kw |

|

YHPE -1800 |

1800mm |

Φ70/Φ60mm |

33:1 |

22/18.5kw |

2.2kw |

1.5kw |

5-30m/min |

105kw |

|

YHPE -2000 |

2000mm |

Φ75/Φ65mm |

33:1 |

30/18.5kw |

2.2kw |

2kw |

5-30m/min |

115kw |

|

YHPE -2500 |

2500mm |

Φ80/Φ70mm |

33:1 |

30/22kw |

3kw |

2.2kw |

5-30m/min |

135kw |

|

YHPE -3000 |

3000mm |

Φ90/Φ80mm |

33:1 |

45/30kw |

3kw |

3kw |

5-30m/min |

158kw |

|

YHPE -3500 |

3500mm |

Φ105/Φ85mm |

33:1 |

55/37kw |

3kw |

3kw |

5-25m/min |

200kw |

*We will no longer inform you it there is any data change.

1. Chiller

2. Automatic Vacuum Feeder

3. Auto Changing Sieve

4. Blender

5. Scrap Reverse

6. Grinder

7. Auto Rewinder

8. In line perforated unit

9. Huangyan T-die